Typical Application

- Cutting Boards Thermoforming

- Chemical Tanks Chair and belt guides

- Light Duty chain guides

- Wear strips, guide rails and neck guides

- Orthotics and prosthetic device

- Water storage Corner tracks

- Food Processing Spiral Conveyors

- Mining Chute Liners Extruded profiles and guide rails

Features

- FDA/USDA Food Handling Guidelines Light-weight

- Chemical and Corrosion Resistant

- Low Moisture Absorption

- High Tensile Strength

- Excellent Impact Resistance

Specifications

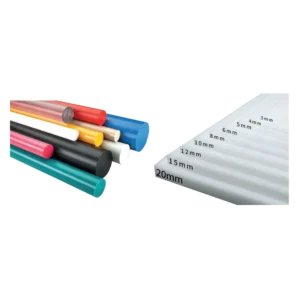

Sheet: Thickness – 1mm-20mm Sizes – 1mt x 2mt, 1.22mt x 2.44mt, 1.2mt x 2mt, 1.5mt x 3mt

Rod: Dia x Length – 16-400mm X 1000mm

Square & Profiles: 16mm x 16mm – 150mm x 150mm

Products

Sheets | Rods | Square Rods | Geo Membrane

Mechanical Properties

| Performance and test conditions |

Test Method |

Unit |

Typical Values |

| Notched impact strength of cantilever beam, 23°C |

ASTM D256 |

J/m |

80 |

| Yield tensile strength, 23°C, 50mm/min |

ASTM D638 |

Mpa |

30 |

| Elongation at break, 23°C, 50mm/min |

ASTM D638 |

% |

500 |

| The bending strength. 23C, 2mm/min |

ASTM 790 |

Mpa |

35 |

| Bending modulus, 23°C, 2mm/min |

ASTM 790 |

Mpa |

1375 |

| Shore hardness D |

ASTMD2240 |

– |

75 |

| The Density |

ISO 1183 |

g/cm3 |

0.96 |

Thermal Performance

| Performance and test conditions |

Test Method |

Unit |

Typical Values |

| Thermal deformation temprature(HDT) (0.45Mpa) |

ISO 75 |

°C |

80 |

| Melting Point |

– |

°C |

120 |

| Long term operating temperature |

– |

°C |

90 |

| Short-term operating temperature |

– |

°C |

110 |

| Thermal conductivity |

DIN 52612-1 |

W/(K-M) |

– |

| Linear expansion coefficient |

ASTM D696 |

10-5-1/K |

15.5 |

Electrical Performance

| Performance and test conditions |

Test Method |

Unit |

Typical Values |

| Dielectric strength |

ASTM D150 |

KV-mm |

40 |

| Dielectric loss coefficient |

ASTM D150 |

– |

– |

| The volume resistance |

ASTM D257 |

Ω.cm |

1014 |

| The surface resistance |

ASTM D257 |

Ω |

1016 |

| Dielectric constant |

ASTM D149 |

– |

2.4 |