Typical Application

- Gear wheels with small modulus Cams

- Heavily loaded bearings and rollers

- Bearing and gears with small clearances

- Valve seats

- Snap fit assemblies

- Snap fit assemblies

- Electrically Insulating Components

Features

- High Mechanical Strength

- Excellent Resilience

- Excellent Machinability

- Physiologically Inert (most grades are suitable for food contact)

Specifications

Sheet: Thickness 6-100mm

SIzes: 610mm x 1200mm X 2000mm, 1000mm x 2000mm

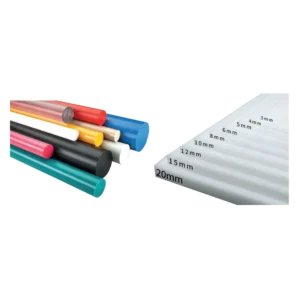

Rod: diameter x length

16-200mm X 1000mm

Products

Sheets | Rods | Square Rods | Profiles

Mechanical Properties

| Performance and test conditions |

Test Method |

Unit |

Typical Values |

| Notched impact strength of cantilever beam, 23°C |

ASTM D256 |

KJ/m² |

10 |

| Yield tensile strength, 23°C, 50mm/min |

ASTM D638 |

Mpa |

60 |

| Elongation at break, 23°C, 50mm/min |

ASTM D638 |

% |

25 |

| The bending strength. 23C, 2mm/min |

ASTM 790 |

Mpa |

70 |

| Bending modulus, 23°C, 2mm/min |

ASTM 790 |

Mpa |

2500 |

| Shore hardness D |

ASTMD2240 |

– |

85 |

| The Density |

ISO 1183 |

g/cm3 |

1.42 |

Thermal Performance

| Performance and test conditions |

Test Method |

Unit |

Typical Values |

| Thermal deformation temprature(HDT) (0.45Mpa) |

ISO 75 |

°C |

120 |

| Melting Point |

– |

°C |

170 |

| Long term operating temperature |

– |

°C |

100 |

| Short-term operating temperature |

– |

°C |

120 |

| Thermal conductivity |

DIN 52612-1 |

W/(K-M) |

0.33 |

| Linear expansion coefficient |

ASTM D696 |

10-5-1/K |

13 |

Electrical Performance

| Performance and test conditions |

Test Method |

Unit |

Typical Values |

| Dielectric strength |

ASTM D150 |

KV-mm |

19 |

| Dielectric loss coefficient |

ASTM D150 |

– |

0.007 |

| The volume resistance |

ASTM D257 |

Ω.cm |

1015 |

| The surface resistance |

ASTM D257 |

Ω |

1015 |

| Dielectric constant |

ASTM D149 |

– |

3.7 |