Number of Fasteners Required

| Belt Width | 16″ | 18″ | 20″ | 24″ | 30″ | 36″ | 42″ | 48″ |

|---|---|---|---|---|---|---|---|---|

| 90° Splice | 13 | 15 | 16 | 20 | 25 | 30 | 35 | 40 |

| 45° Splice | 16 | 18 | 21 | 25 | 33 | 40 | 47 | 54 |

Care should be taken in selecting the Correct Jupiter/Balaji Standard Fasteners for the belt thickness. Also sizes of pulleys used should be in accordance with our recommendation. Too large a fastener will not flex properly over the pulleys causing the belt to crack at the joint. Too small a fastener decreases the strength of the splice and may cause breakage at the joint.

The plates have been designed for extra long wearing life. Strength of all Jupiter Heavy Duty bolts and nuts has been increased to withstand the stress of power Tools now commonly used in the installation of belt fasteners.

When a Conveyor belt is down, all work stops and costly loss of production and labour begins. The belt repairman becomes the most important man in the Plant. To help save time in getting the belt back in service all Fasteners are boxed with the bolts and clip assembled in the bottom Plate. This a real time saver and helps to reduce to a minimum the time required to get any Conveyor back in receive.

How to join conveyor Belt by using Jupiter Heavy Duty plate / hawk type Belt Fasteners :

Place the square ends of the belt together and nail the Template in position, taking case that the lags the belt ends. Bend the nails outwards to prevent the template raising from the belts surface and then punch the holes using a 3/16″-3/8” Belt Punch.

Remove the template. Push the Bolt ends through the punch hole from the underside of the belt and place the top plate in position (uses will find added assistance employing the Bolthom)

Apply the stored nuts loosely by hand, making sure that the plates are aligned accurately. Tighten the nuts firmly and evenly with a 5/16” wrench for No. 1, No. 1 1 /2 and No. 2 belt fasteners and with a 3/8” wrench for No. 2 ½ and No. 3.

Hammer the plates into the belt surface using a metal block placed across the fasteners and between the nuts. Once again tighten the nuts and then break of the producing ends of the bolts, using a Bolt Breaker.

It is advisable to re-tighten the nuts once again, after the belt has been working for a few hours.

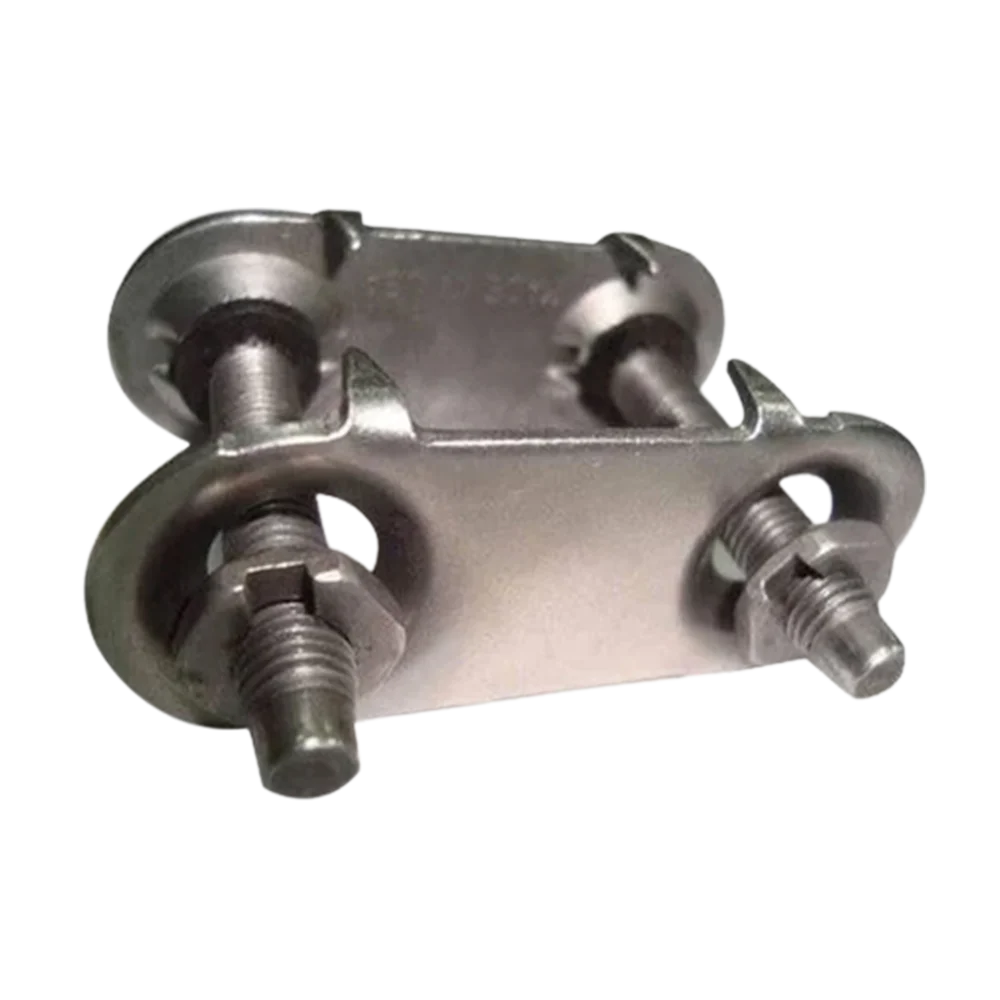

Balaji International Bolt Solid Plate Fastener System

Balaji International Bolt Solid Plate fasteners are engineered to meet the demands of the toughest material handling applications, providing a strong sift-free splice and superior holding ability. A choice of sizes accommodates belts from 3/16″ (5 mm) to over 15/16″ (24 mm) thick.

High Strength

High strength is the result of superior design and plate compression on both the top and bottom sides of the belt. High tensile strength bolts compress top and bottom plates to distribute splice tension evenly across the entire width of each fastener plate. For added strength and pull-out resistance, specially formed teeth penetrate deep into the belt carcass – without damaging carcass fibers.

Easy Installation

Field-proven templates, punches, and boring tools make it easy to quickly and accurately prepare belts for fastener installation. Fasteners are easily installed on-site using portable hand tools or power tools. Our exclusive piloted bolts also contribute to faster installation.

Market Applications

- Sand

- Gravel

- Crushed stone

- Grain

- Coal

- Cement

- Salt

Solid Plate Fastener Selection Guide

| Fastener Size | Belt Thickness Range | For Belts with Mechanical Fastener Ratings Up To: |

Recommended Minimum Pulley Diameter (Operating Tension 75% -100% of Belt Rating) |

|||

|---|---|---|---|---|---|---|

| in. | mm | P.I.W. | kN/m | in. | mm | |

| 1 | 3/16-7/16 | 5- 11 | 150 | 30 | 12 | 300 |

| 140 | 3/16-7/16 | 5- 11 | 225 | 40 | 14 | 350 |

| 190 | 5/16-9/16 | 8 – 14 | 330 | 60 | 18 | 450 |

| 1-1/2 | 7/16- 11/16 | 11 – 17 | 300 | 50 | 18 | 450 |

| 2 | 9/16- 13/16 | 14-21 | 440 | 75 | 30 | 750 |

| 2-1/4 | 9/16- 1-3/16 | 14-30 | 620 | 105 | 36 | 900 |

| 2-1/2 | 3/4- 1 | 19-25 | 450 | 75 | 42 | 1050 |

| 3 | 15/16 & over | 24 & over | 560 | 100 | 48 | 1200 |