In the bustling world of industrial operations, rubber conveyor belts are the unsung heroes that keep production lines moving. From mining sites to food processing plants, these durable belts transport materials efficiently, reducing downtime and boosting productivity. However, not all conveyor belts are created equal, and selecting a subpar product can lead to costly breakdowns, safety hazards, and operational inefficiencies. That’s why partnering with a reliable rubber conveyor belt exporter is crucial. With the global market flooded with options, especially from manufacturers in China, India, and Europe, knowing how to choose wisely can save you time, money, and headaches. This comprehensive guide walks you through the essential steps and factors to consider when selecting a trustworthy exporter, ensuring you get high-quality belts that stand the test of time.

Why Quality Matters in Rubber Conveyor Belts

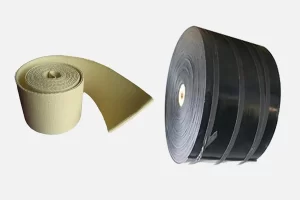

Rubber conveyor belts are engineered to handle heavy loads, abrasive materials, and harsh environments. Made from layers of rubber compounds reinforced with fabrics like nylon or steel cords, they must resist wear, tear, and environmental factors like heat, moisture, and chemicals. A reliable exporter ensures these belts meet industry standards, such as those from ISO or DIN, preventing issues like belt slippage, elongation, or premature failure. Poor-quality belts can halt operations, leading to lost revenue studies show that conveyor belt failures cost industries millions annually. By choosing a dependable exporter, you’re investing in durability, compliance, and peace of mind.

Key Factors to Evaluate in a Rubber Conveyor Belt Exporter

When vetting potential exporters, focus on criteria that reflect their commitment to excellence. Here’s a breakdown of the most important aspects:

Certifications and Compliance Standards

Certifications are your first line of defense against unreliable suppliers. Look for exporters certified under ISO 9001 for quality management systems, ensuring consistent production processes. Additionally, check for industry-specific standards like ISO 14890 for conveyor belts or certifications from bodies like the American Society for Testing and Materials (ASTM). Compliance with safety regulations, such as those from OSHA or EU directives, indicates the exporter prioritizes worker safety and environmental responsibility. Avoid exporters without these credentials, as they might cut corners on materials or testing.

Reputation and Track Record

A exporter’s reputation speaks volumes. Research their history by checking online reviews on platforms like Alibaba, ThomasNet, or industry forums. Look for testimonials from clients in similar sectors positive feedback on delivery times, product longevity, and customer service is a green flag. Established exporters with years of experience, such as those exporting to global markets for decades, are often more reliable. If possible, ask for references and contact past clients to verify claims. A strong track record in handling custom orders or large-scale projects can set a supplier apart.

Product Quality and Customization Options

Quality starts with the materials. Reliable exporters use premium rubber compounds, like EPDM or neoprene, sourced from reputable suppliers to ensure resistance to oils, acids, and extreme temperatures. Inspect samples for uniformity, tensile strength, and flexibility. Customization is key whether you need belts for incline conveying, food-grade applications, or heavy-duty mining, a good exporter should offer tailored solutions. Ask about their testing protocols, including tensile tests, abrasion resistance checks, and flame retardancy for hazardous environments. High-quality belts often come with warranties, guaranteeing performance for a specified period.

Pricing and Value for Money

While cost is important, the cheapest option isn’t always the best. Compare quotes from multiple exporters, factoring in total cost of ownership including shipping, installation, and maintenance. Reliable suppliers provide transparent pricing without hidden fees and may offer volume discounts for bulk orders. Beware of suspiciously low prices, which could signal inferior materials or unethical practices. Instead, focus on value: a slightly higher upfront cost for a durable belt that lasts longer often pays off in reduced replacements and downtime.

Manufacturing Capabilities and Technology

Touring a exporter’s facility can reveal much about their operations. Modern exporters invest in advanced machinery, such as automated vulcanizing presses and computerized testing equipment, to produce consistent belts. Inquire about their production capacity can they handle your order volume without delays? Technology like AI-driven quality control ensures defects are caught early. For international exporters, proximity to ports or efficient logistics can affect delivery times. If a virtual tour isn’t possible, request detailed photos or videos of their processes.

Customer Service and Support

Reliability extends beyond the product to after-sales support. A trustworthy exporter offers responsive communication, clear documentation, and assistance with installation or troubleshooting. Check their response times to inquiries and availability of technical experts. Good exporters provide training for your team and ongoing support, such as spare parts availability. In a global market, language barriers can be an issue, so opt for suppliers with English-speaking representatives or multilingual teams.

Research and Evaluation Methods

Choosing a reliable exporter requires thorough research. Start by using online directories like Made-in-China or Indiamart to shortlist suppliers based on your requirements. Attend trade shows, such as the International Rubber Conference or Hannover Messe, to network and inspect products first-hand. Engage with industry associations like the Rubber Manufacturers Association for recommendations. Once shortlisted, request detailed proposals, including specifications, lead times, and payment terms. Conduct a risk assessment by evaluating their financial stability publicly traded companies or those with audited financials are preferable.

Common Pitfalls to Avoid

Even seasoned buyers can fall into traps. Avoid exporters who pressure for quick decisions or lack verifiable contact information these could be scams. Steer clear of those ignoring environmental standards, as non-compliant belts might face import bans. Don’t overlook logistics; poor packaging can damage belts during transit. Finally, resist the urge to base decisions solely on price; quality compromises can lead to regrets.

Real-World Examples and Case Studies

Consider a mining company that sourced belts from a certified exporter in Germany. Despite higher costs, the belts’ superior abrasion resistance reduced replacements by 30%, saving thousands. Conversely, a food processor in the U.S. chose a low-cost Asian supplier without certifications, resulting in belt failures that contaminated products and led to recalls. These stories highlight the importance of due diligence.

Making an Informed Decision

Selecting a reliable rubber conveyor belt exporter is about balancing quality, cost, and trust. By prioritizing certifications, reputation, and product integrity, you can avoid pitfalls and secure belts that enhance your operations. Remember, the right partner isn’t just a vendor it’s a long-term ally in your success. Take the time to research thoroughly, and you’ll reap the benefits of efficient, durable conveyor systems. If you’re in the market, start by listing your needs and reaching out to potential exporters today. Your production line will thank you.