In the world of industrial finishing and polishing, achieving a flawless surface finish is often a critical step in the manufacturing process. Whether you are working with metals, glass, plastics, or wood, the right polishing tools can make all the difference in the quality, efficiency, and cost-effectiveness of your operations. Among these tools, felt polishing rings stand out as versatile and effective components used in various industries to deliver smooth, shiny, and precise finishes.

However, not all felt polishing rings are created equal. Selecting the right felt polishing ring tailored to your specific industrial application is essential to optimize performance, extend tool life, and ensure consistent results. This comprehensive guide will walk you through the key factors to consider when choosing felt polishing rings for your industrial needs.

What Are Felt Polishing Rings?

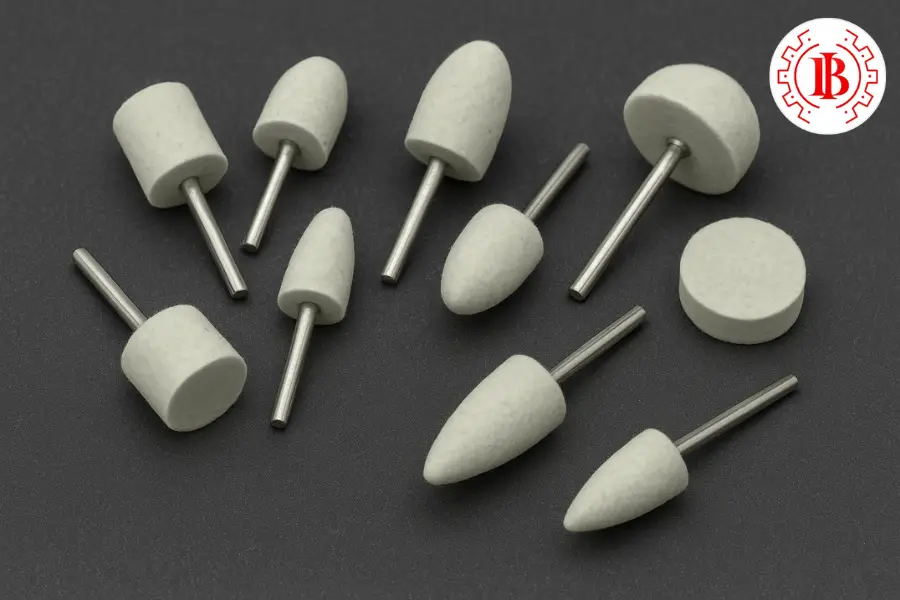

Felt polishing rings are circular polishing tools made from compressed wool or synthetic felt materials. They are designed to be mounted on rotary tools, polishing machines, or buffing wheels and are used in conjunction with polishing compounds to smooth and shine surfaces. Their soft yet durable texture allows them to conform to the contours of the workpiece, making them ideal for finishing intricate shapes and delicate surfaces.

Why Felt Polishing Rings Are Popular in Industry

- Versatility: Suitable for polishing metals, glass, ceramics, plastics, and wood.

- Precision: Their soft texture allows for detailed polishing on complex geometries.

- Durability: High-quality felt rings withstand repeated use without significant wear.

- Cost-Effectiveness: Reusable and compatible with various polishing compounds.

Surface Quality: Capable of achieving mirror-like finishes when used correctly.

Key Factors to Consider When Choosing Felt Polishing Rings

Material Composition

The material of the felt polishing ring significantly influences its performance and suitability for different applications.

- Natural Wool Felt: Made from compressed wool fibers, natural felt offers excellent absorbency and softness. It is ideal for polishing delicate surfaces and achieving high gloss finishes. Wool felt is often preferred in jewelry making, optics, and fine metal polishing.

- Synthetic Felt: Manufactured from polyester or other synthetic fibers, synthetic felt tends to be more durable and resistant to chemicals and moisture. It is suitable for heavy-duty polishing tasks and environments where natural fibers may degrade quickly.

- Choosing Tip: For delicate or precision polishing, opt for natural wool felt. For industrial applications requiring chemical resistance and durability, synthetic felt is preferable.

Density and Hardness

Felt polishing rings come in various densities, affecting their hardness and polishing characteristics.

- Soft Felt Rings: Softer rings conform better to irregular surfaces and are excellent for fine polishing and buffing.

- Hard Felt Rings: Denser and firmer, these rings are better suited for initial polishing stages where more abrasive action is needed.

- Choosing Tip: Match the felt density to the polishing stage start with harder rings for rough polishing and switch to softer rings for finishing.

Size and Thickness

The dimensions of the felt polishing ring must align with your polishing equipment and the size of the workpieces.

- Diameter: Ensure the ring fits securely on your rotary tool or polishing machine without wobbling.

- Thickness: Thicker rings provide longer service life and better cushioning but may reduce precision on small or intricate parts.

- Choosing Tip: Measure your equipment’s spindle or mandrel size and select felt rings accordingly. For detailed work, thinner rings may offer better control.

Compatibility with Polishing Compounds

Felt polishing rings are typically used with polishing compounds such as rouge, diamond paste, or cerium oxide.

- Absorbency: Natural felt absorbs and holds polishing compounds well, enhancing polishing efficiency.

- Chemical Resistance: Synthetic felt may be necessary when using aggressive or solvent-based compounds.

- Choosing Tip: Verify that the felt material is compatible with the polishing compounds you intend to use to avoid degradation or reduced effectiveness.

Application and Surface Type

Different industries and materials require specific polishing approaches.

- Metals: For stainless steel, brass, aluminum, or precious metals, select felt rings that can achieve the desired finish without scratching.

Glass and - Ceramics: Use soft, fine-density felt rings to avoid surface damage.

Plastics and - Composites: Choose felt rings that minimize heat generation to prevent melting or warping.

- Wood: Felt rings can be used for final buffing to enhance grain and shine.

- Choosing Tip: Understand the material properties of your workpiece and select felt rings designed for those surfaces.

Speed and Machine Compatibility

The operational speed of your polishing equipment affects felt ring performance.

- High-Speed Machines: Require felt rings that can withstand centrifugal forces without deforming.

- Low-Speed Machines: Allow for softer, more delicate felt rings.

- Choosing Tip: Consult manufacturer specifications to ensure the felt ring’s maximum RPM rating matches your equipment.

Additional Considerations

- Durability and Maintenance

High-quality felt polishing rings should maintain their shape and effectiveness over multiple uses. Regular cleaning and conditioning with polishing compounds can extend their lifespan. - Cost vs. Performance

While cheaper felt rings may seem attractive, investing in premium quality rings often results in better finishes, longer tool life, and reduced downtime. - Customization Options

Some manufacturers offer custom-sized or shaped felt polishing rings tailored to unique industrial needs, which can improve efficiency and results.

Practical Tips for Using Felt Polishing Rings

- Proper Mounting: Ensure the ring is securely mounted to avoid wobbling or uneven polishing.

Compound - Application: Apply polishing compounds evenly and sparingly to avoid buildup.

- Pressure Control: Use light to moderate pressure to prevent overheating and material damage.

Regular - Inspection: Check felt rings for wear and replace them when they lose effectiveness.

Choosing the right felt polishing ring for your industrial application is a critical decision that impacts the quality of your finished products, operational efficiency, and overall cost-effectiveness. By considering factors such as material composition, density, size, compatibility with polishing compounds, and the specific requirements of your workpiece and equipment, you can select felt polishing rings that deliver optimal performance.

Whether you are polishing delicate jewelry pieces, automotive parts, glass components, or wooden furniture, the right felt polishing ring will help you achieve a flawless finish with precision and ease. Partnering with reputable manufacturers who offer high-quality, customizable felt polishing rings can further enhance your polishing processes and ensure consistent, professional results.

Invest time in understanding your polishing needs and selecting the appropriate felt polishing rings your surfaces will thank you with a brilliant shine and impeccable smoothness.