Conveyor belts are essential for optimizing processes and raising output in the manufacturing and logistics sectors. Whether you are in the food processing, automotive, packaging, or any other industry that relies on material handling, selecting the right conveyor belt supplier is essential for ensuring the efficiency and reliability of your operations. It might be difficult to choose the supplier that best suits your needs when there are so many to choose from. This article outlines the key factors to consider when choosing a conveyor belt supplier to help you make an informed decision.

Quality of Products

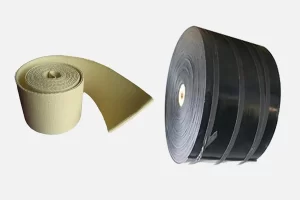

The quality of the conveyor belts offered by a supplier is perhaps the most critical factor to consider. High-quality conveyor belts are essential for ensuring smooth operations, minimizing downtime, and reducing maintenance costs. When evaluating potential suppliers, inquire about the materials used in their conveyor belts. Look for suppliers that use durable materials, such as rubber, PVC, or polyurethane, which can withstand the rigors of your specific application.

Take into account the supplier’s manufacturing procedures as well. A reputable supplier should adhere to industry standards and quality control measures to ensure that their products meet or exceed performance expectations. A dedication to quality control and reliable product performance can be shown by certifications like ISO 9001.

Range of Products

Different industries and applications require various types of conveyor belts. When choosing a supplier, it is essential to assess the range of products they offer. A supplier with a diverse selection of conveyor belts can better cater to your specific needs, whether you require modular belts, flat belts, timing belts, or specialty belts designed for unique applications.

Moreover, consider whether the supplier offers customization options. Custom conveyor belts can be tailored to meet specific requirements, such as size, thickness, and surface texture. A supplier that provides customization demonstrates a willingness to work closely with clients to develop solutions that enhance operational efficiency.

Industry Experience and Expertise

The experience and expertise of a conveyor belt supplier can significantly impact the quality of their products and services. Suppliers with a long-standing presence in the industry are more likely to have a deep understanding of the challenges faced by various sectors and can offer valuable insights and recommendations.

When evaluating potential suppliers, consider their track record and reputation within the industry. Look for testimonials, case studies, and references from other clients to gauge their level of expertise and customer satisfaction. A supplier with a proven history of successful projects is more likely to deliver reliable products and services.

Customer Support and Service

Excellent customer support is a vital quality to look for in a conveyor belt supplier. The relationship between a supplier and their clients should extend beyond the initial sale. A reliable supplier should provide ongoing support, including assistance with product selection, installation guidance, and troubleshooting.

Ask about the resources and technical help that are available. Does the supplier offer comprehensive product documentation, installation manuals, and maintenance guidelines? A supplier that provides these resources demonstrates a commitment to helping customers achieve optimal performance from their conveyor systems.

Additionally, responsive customer service is essential. When issues arise or questions need to be addressed, having a dedicated support team that can provide timely assistance can make a significant difference in your overall experience. Look for suppliers with positive reviews regarding their customer service, as this can be an indicator of their reliability and commitment to client satisfaction.

Pricing and Value

While cost is an important consideration, it should not be the sole determining factor in your decision. When evaluating conveyor belt suppliers, consider the overall value they offer rather than just the price of their products. A lower price may be tempting, but it could come at the expense of quality or customer service.

Assess the total cost of ownership, which includes not only the initial purchase price but also factors such as maintenance, replacement, and downtime costs. A higher-quality conveyor belt may have a higher upfront cost but can lead to significant savings in the long run due to reduced maintenance and increased operational efficiency.

Delivery and Lead Times

Timely delivery is crucial in maintaining smooth operations, especially in industries where downtime can lead to significant losses. When choosing a conveyor belt supplier, inquire about their lead times and delivery capabilities. A reliable supplier should be able to provide accurate estimates for product availability and shipping times.

Take into account the supplier’s capacity to manage last-minute requests or urgent orders as well. A supplier that can accommodate quick turnaround times demonstrates flexibility and a commitment to meeting customer needs.

Sustainability Practices

As sustainability becomes an increasingly important consideration in manufacturing and logistics, it is essential to evaluate the environmental practices of potential conveyor belt suppliers. Look for suppliers that prioritize eco-friendly materials and production processes. This not only benefits the planet but can also enhance your company’s reputation as a socially responsible business.

Inquire about the supplier’s approach to waste management, recycling, and energy efficiency in their manufacturing processes. A supplier that is committed to sustainability can help you align your operations with environmentally friendly practices.

Innovation and Technology

The conveyor belt industry is continually evolving, with new technologies and innovations emerging to improve efficiency and performance. Take into account a supplier’s dedication to research and development before choosing one. A manufacturer that invests in innovation is more likely to produce advanced conveyor belts that utilize the latest technologies, such as smart sensors and automation features.

Additionally, inquire about the supplier’s willingness to adapt to changing industry trends and customer needs. A forward-thinking supplier can provide you with cutting-edge solutions that enhance your operational capabilities.

Choosing the right conveyor belt supplier is a critical decision that can significantly impact the efficiency and reliability of your operations. By considering factors such as product quality, range of offerings, industry experience, customer support, pricing, delivery capabilities, sustainability practices, and innovation, you can make an informed choice that aligns with your specific needs.

Investing time in selecting a reputable conveyor belt supplier will pay off in the long run, ensuring that you receive high-quality products and services that enhance your material handling processes. Whether you are a small business or a large industrial operation, prioritizing these qualities will help you find a reliable partner in achieving your operational goals.